Vero Wireless Vibration Sensors

Remote condition monitoring system that eliminates unplanned downtime.

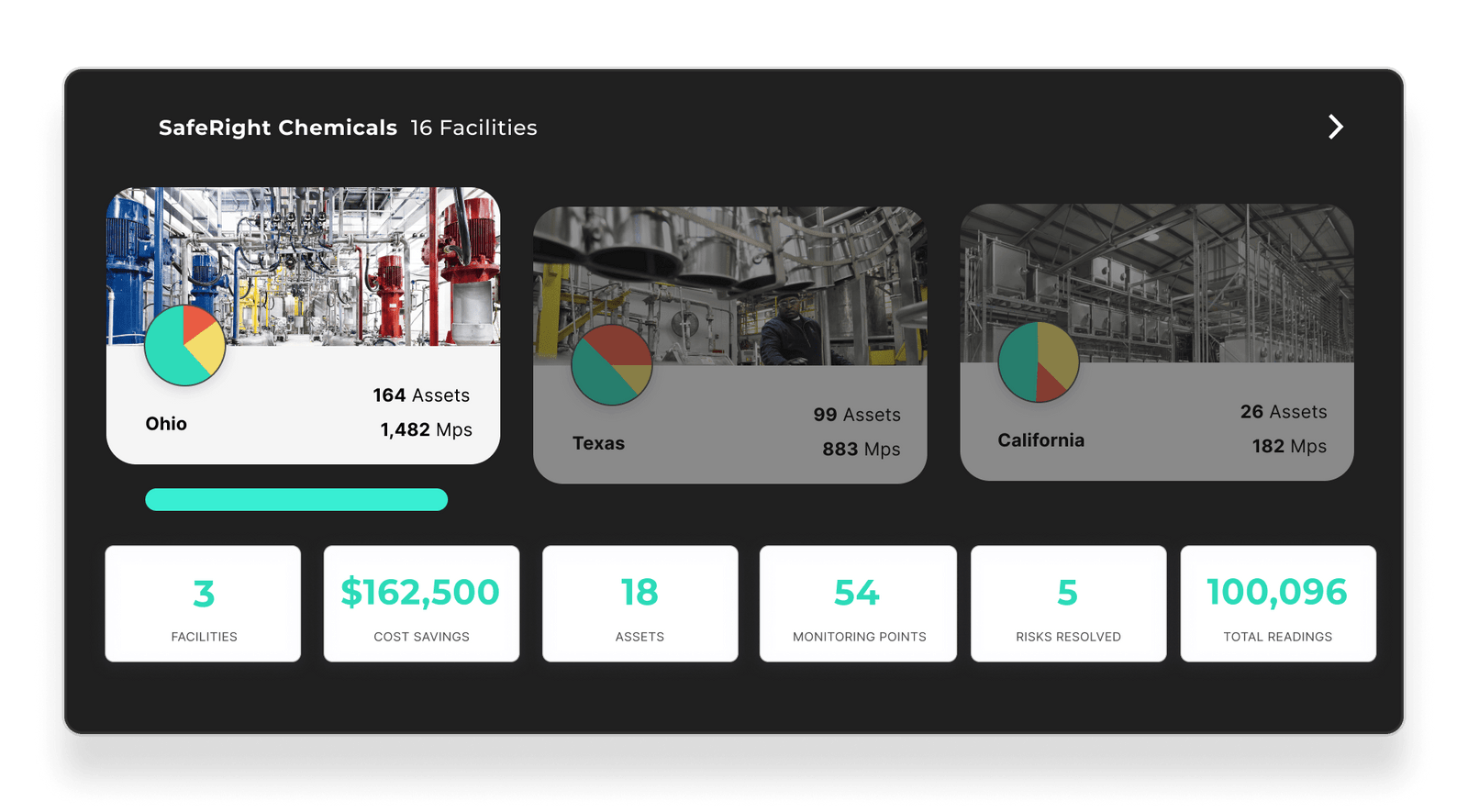

Monitor your entire facility, or across your entire enterprise, in one command center.

Book your 30 minute demo today!

We want to hear about your manufacturing process, critical rotating equipment, and reliability challenges, as well as share how our vibration monitoring system has helped hundreds of customers prevent downtime, improve efficiencies, and save their company a lot of money. Book your demo today and see how AssetWatch remote vibration monitoring can make you a reliability hero.

Sign up for a free demo!

How it Works

![How-it-Works_Install_resized_v2[2065513]](https://go.assetwatch.com/hubfs/How-it-Works_Install_resized_v2%5B2065513%5D.jpg)

01 | Install

We rapidly deploy so you don’t have to! Installation of the Vero vibration monitoring equipment usually takes less than 1 day to complete. And did we mention the lifetime warranty? Plus, our support team will set up the facility and assets in the AssetWatch software platform for you.

02 | Connect

Maintenance-free, wireless cellular-communication hubs and cradle points are included in the installation and price. No capex, no engineering, and no network integration required. AssetWatch gets your vibration monitoring system up and running quickly so you can start showing ROI right away.

![How-it-Works-Analyze[12133]](https://go.assetwatch.com/hubfs/How-it-Works-Analyze%5B12133%5D.jpg)

03 | Analyze

Powered by machine learning and AI, the AssetWatch platform has proprietary algorithms to detect anomalies and prioritize asset risks early so you can maintain rotating machine health and improve uptime.

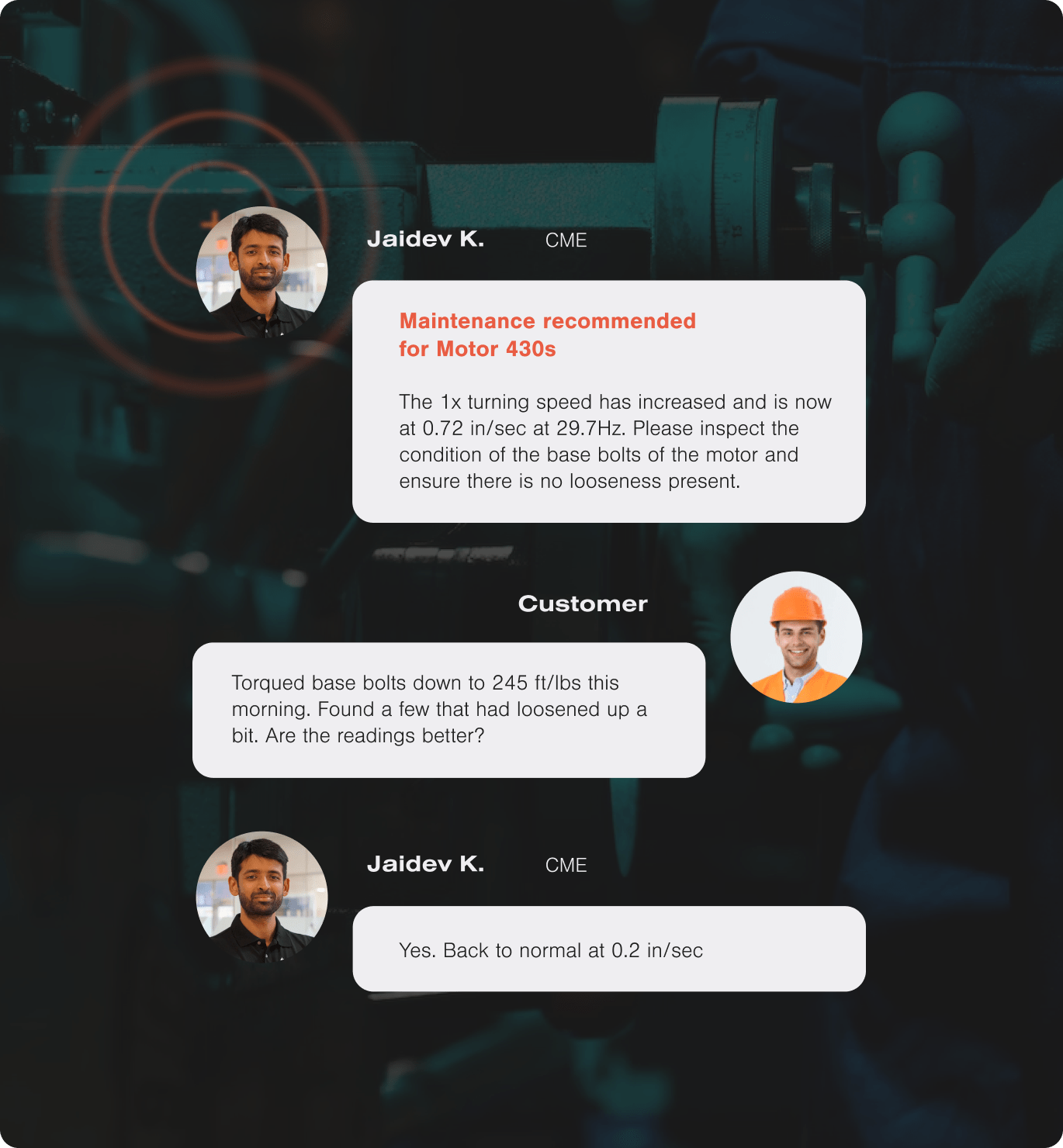

04 | Partner

What makes AssetWatch extra special is our ability to turn data into action. You will have a dedicated Condition Monitoring Engineer (CME) as your partner to provide prescriptive maintenance recommendations via 2-way communication in the mobile app and platform, detailing specific steps your team can take to address the problem and then track the ROI. Before the trial even begins, your CME will work with you to review your facility’s assets and determine which ones will drive the highest ROI through condition monitoring.

Quickly Deployable, Hassle-Free Solution

Discover the AssetWatch advantage and how it works in our explainer video.

Manufacturing facilities worldwide face common challenges: stressed equipment, unplanned downtime, strained personnel, managing multiple vendors, and overwhelming data. AssetWatch solves these challenges with an end-to-end condition monitoring solution that provides a comprehensive view of your asset health– from a single monitoring point to an enterprise level view. Even better, we do the installation for you, analyze the data, and provide prescriptive maintenance recommendations so you can maximize your team's valuable time.

What to do in AssetWatch

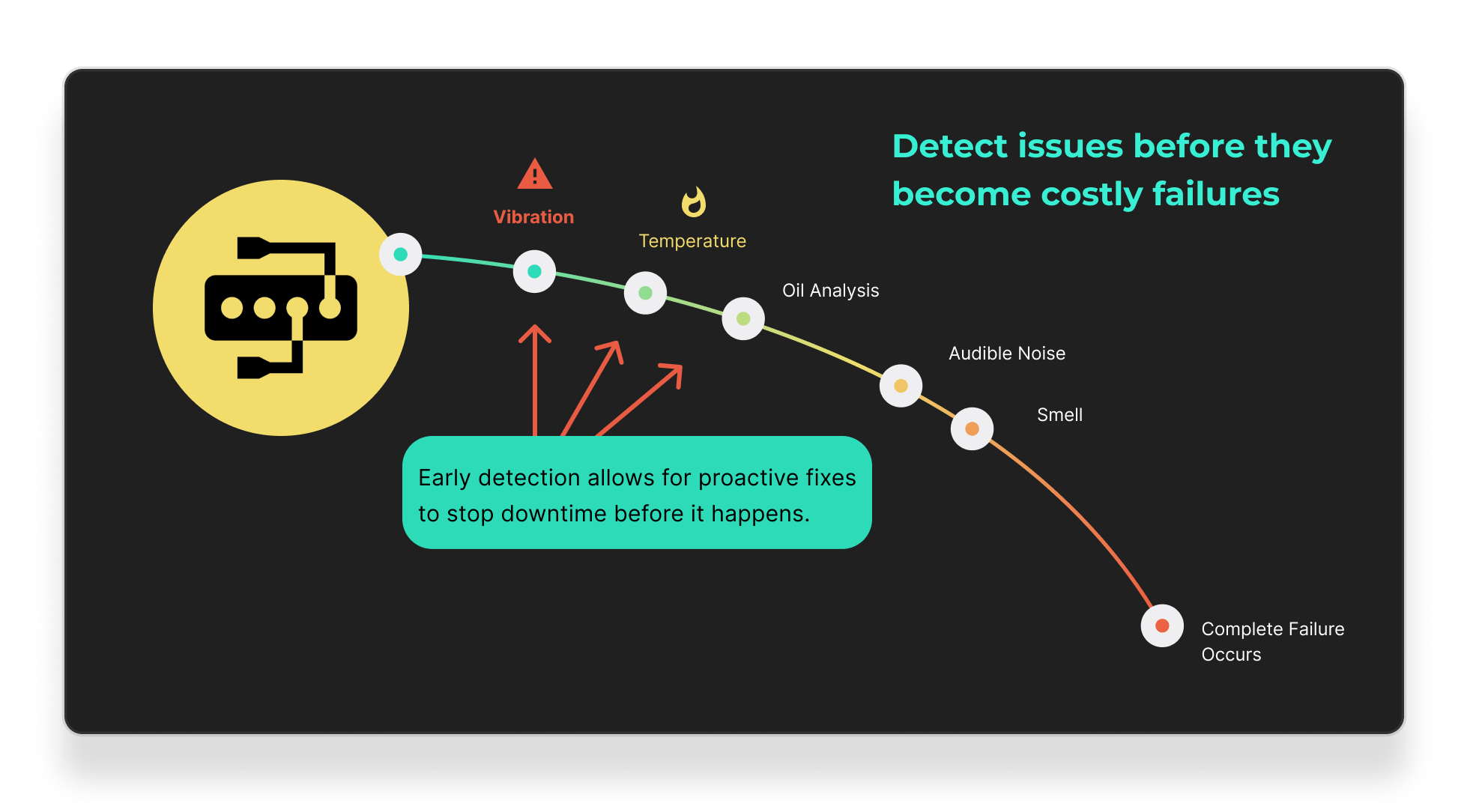

Early Anomaly Detection

.png)

Our advanced AI detects issues in their infancy, ranks risk level, and raises concern to your dedicated Condition Monitoring Engineer (CME). This unique combination of machine learning and the experience of a certified CAT III vibration analyst cuts through the noise of data and prevents you from having an overwhelming flood of alerts.

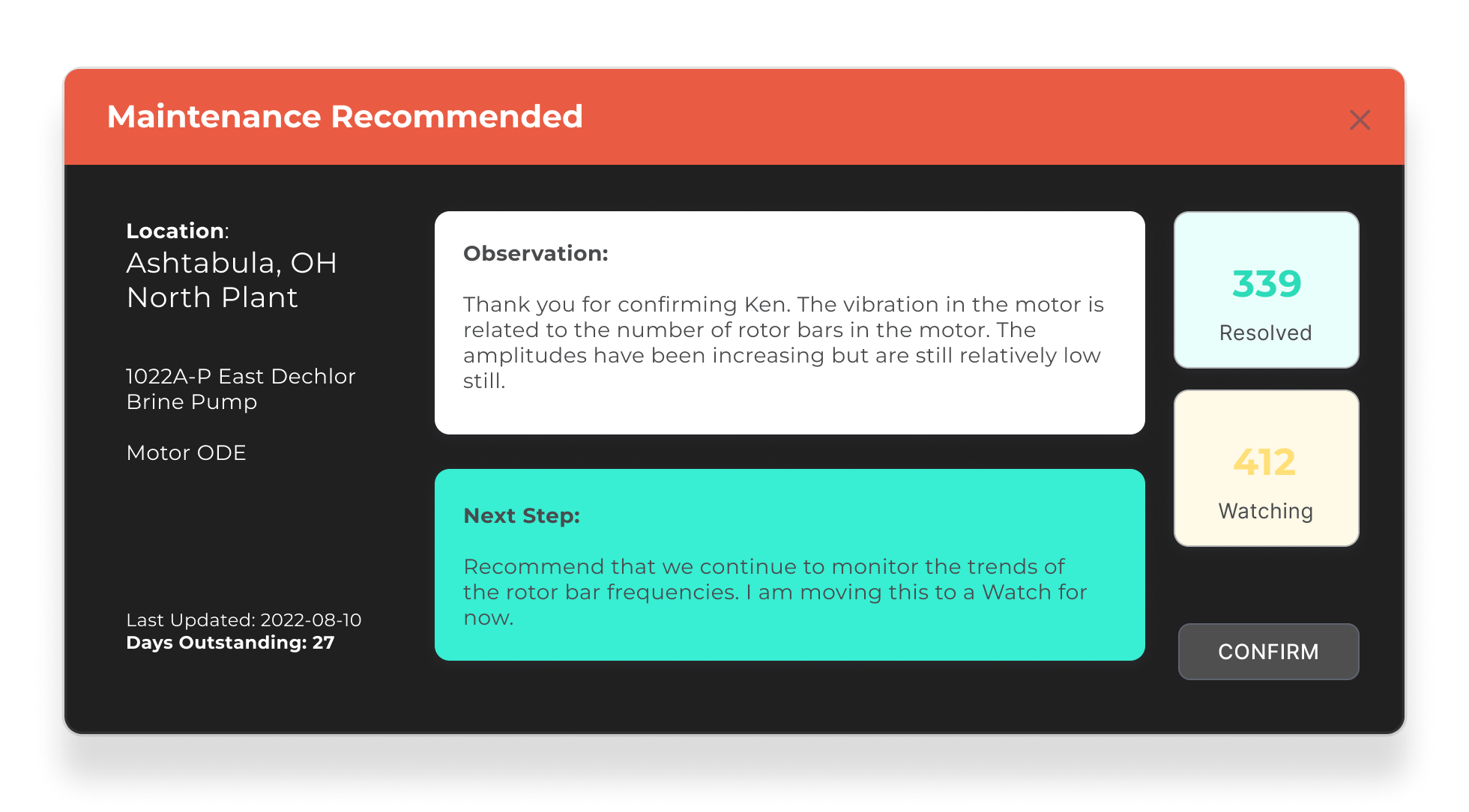

Prescriptive Insights

Efficient 2-way communication through AssetWatch makes issue resolution easy, fast, and documented. When an anomaly is detected by AssetWatch, your CME will send a prescriptive asset alert with detailed next steps your team can take to resolve the problem. Your CME will collaborate with you until the issue is resolved.

Dynamic ROI

AssetWatch helps you preemptively resolve issues before costly failure, making you the hero to leadership as you increase uptime and extend and maximize the life of your assets. The proof is in the numbers, and we help you track it all in one place so you can easily report on success to management.

Multi-Facility View

Our enterprise customers need a quick glance of how each facility is performing. The multi-facility dashboard provides the high-level view management needs, while also being able to drill down at the plant level.